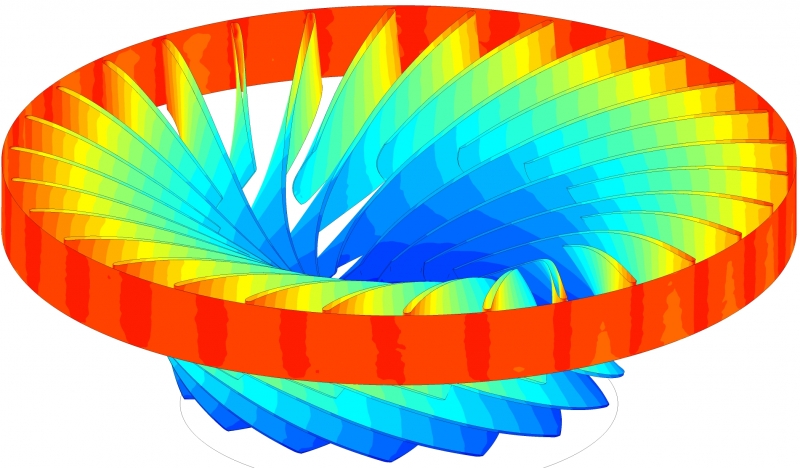

Task 3.3: Validation of the turbine design through model turbine experiments

This task aim to verify the Francis turbine design through experimental investigation of the hydraulic and mechanical performance. The experimental investigation will consist of efficiency-, velocity-, pressure- and strain-measurements of the Francis model turbine under steady state and transient operation such as start-stop and load variations. The measurements will be carried out in the Waterpower Laboratory at NTNU, Norway. The model turbines will be mechanically designed, manufactured and installed in the laboratory followed by the calibration of all measurement equipment. The model turbine measurements will follow the IEC60193 standard in order to ensure good quality of the efficiency measurements. Methodology, equipment and experience from earlier work will be utilized. Strain, force, pressure and velocity measurements will be performed with focus on the runner region and they will be carried out with high quality sensors. The measured parameters will be used as input to WP4 and WP5.

Deliverables and milestones

D3.3 – Recommendations for the hydraulic design of variable speed Francis turbines

Milestones:

- MS40 – HydroFlex tool launch

D3.7 – Report from model turbine experiments

Milestones:

- MS12 – Model turbine is installed and all instrumentation has been calibrated in the Waterpower laboratory at NTNU

- MS13 – Reports from the comparison of the Francis model tests and the numerical analysis